ccp metal detector

75 of the audits done by auditing bodies encounter a non-conformance issue with CCP metal detectors. Download the Practical Guide to Metal Detectors Basics for GFSI Audits Audits are a time consuming yet an imperative part of food production.

Haccp For Frozen Mackerel Production Download Table

For example the metal detector may have failed to identify one of the check pieces the internal temperature may be too cold for a cooking CCP or the internal temperature may be too hot for a cooling CCP.

. If the establishments detection equipment is appropriately calibrated and finds product with foreign material contamination within the level of detection the CCP is operating as designed eg a metal detector rejects packages of hot dogs. Doing the CCP Metal Detector checks every half hour. However because of the metallised nature of the packaging film used it becomes challenging ensuring the metal detection ccp3 step rejects consistently only packs with physical metal contaminants and not false rejects.

Critical Control Points CCPs Evidence of Effectiveness Critical Limits Annually or Significant Change Qualified Individual Chemical Physical Biological Radiological Naturally Occurring Intentional Preventive Control Points including. The quality technician reported a failure of a prescribed test wand or a failure to meet a preventive control parameter. Goedkoopste Metaaldetectors vind je op beslistnl.

Shop eenvoudig en snel online. Process Controls and Allergen Controls Evidence of Effectiveness. All that being said in the baking industry here in the USA metal detection as a CCP is pretty much the industry standard.

So the question really is if there is ANY chance a piece of hazardous metal can be introduced into your product after the first metal detector. 12 process process is food manufacturing of roasted coffee beans andor roasted ground coffee products packed in a protective. A CCP is the last control to remove a hazard or reduce it to an acceptable level that without its control the hazard is reasonably likely to cause illness or injury.

The establishment should evaluate the rejected product and based on the findings of the. Calle 18 113C por 50B y 52 Colonia Itzimná CP. The presence of a metal detector does not automatically require that it be designated as a CCP.

When an auditor asks for metal detection validation its quite common for them to be given the servicing records for the metal detector or the metal detection calibration as its sometimes known. However if the hazard analysis determines that metal is a food safety hazard reasonably likely to occur 9 CFR 4172 c 2 requires that the HACCP plan include at least one CCP to control it and thus the metal detector may be a CCP. The purpose of the CCP metal detection requires that you understand how your detector works so in this issue we help you learn more about it.

In this article were going to cover how we should validate the test pieces we use to monitor our CCP of metal detection. For example a CCP that may be identified in a grain facilitys HACCP plan is the metal detector for ensuring no metal contamination in finished product. Distribuidora Mexicana Hermes Internacional SA.

Still confused on OPRP and CCP in an ISO 22000 Catering Business. Ad Grootste assortiment Metaaldetectors vind je op beslistnl. If you say your metal detector will prevent or eliminate a food safety hazard or reduce it to an acceptable level and someone is injured by a 3mm piece of stainless steel you open yourself up legally.

It all depends on your plant process and product. Over the next few articles Im going to talk about the CCP metal detection. Checking CCP documentation each shift.

Principle 1 Conduct a hazard analysis Principle 2 Determine critical control points CCPs Principle 3 Establish critical limits Principle 4 Establish monitoring procedures for each CCP Principle 5 Establish corrective actions Principle 6 Establish verification procedures Principle 7. The seven HACCP principles are. After checking the metal detector with the test wandsstandards the results must be entered immediately.

To say that the critical limit for the metal detector is no metal in finished product is insufficient as this is not clearly defined. Corrective Action Product Control During production a quality technician was performing a metal detector check as designated by the preventive control or HACCP CCP. Often this step of the process is considered significantly risky to be classified as a CCP Critical Control Point - most food auditors insist it is anyway.

Decision Tree using for. Food Safety - ISO 22000 HACCP 21 CFR 120 1. The use of electronic metal detectors is complex especially with regard to stainless steel which is dificult to detect.

How metal detectors work where the test pieces should go and why we carry out the tests we do. New metal detector ccp -help. Wacht niet langer en haal em in huis.

The orientation of the metal object in the food affects the ability of the. Allergens are an example of a physical food safety hazard. 97100 Mérida Yucatán México Phone.

When a CCP fails it is typically identified by the person monitoring during the CCP check. Food Safety - ISO 22000 HACCP 21 CFR 120 3. The table below will provide more insight into the differences between metal detectors and magnetic separators and the types of contamination each metal fragment control targets.

In some applications it may be appropriate and acceptable for the magnet to be a CCP. Generally most companies in the food industries today have Metal Detectors in their process lines designed for the purpose of detecting metal hazards.

Haccp Introduction 7 Principles Haccp Introduction 7 Principles

Metal Detection Or X Ray Inspection What Food Processors Should Know

Hazard Analysis Critical Control Point Haccp Prezentaciya Onlajn

Metal Detection Or X Ray Inspection What Food Processors Should Know

Flow Diagram Of Biscuit Manufacture Download Scientific Diagram

Summary Of The Of Haccp Plan With The Hazard Identified Download Table

Haccp Introduction 7 Principles Haccp Introduction 7 Principles

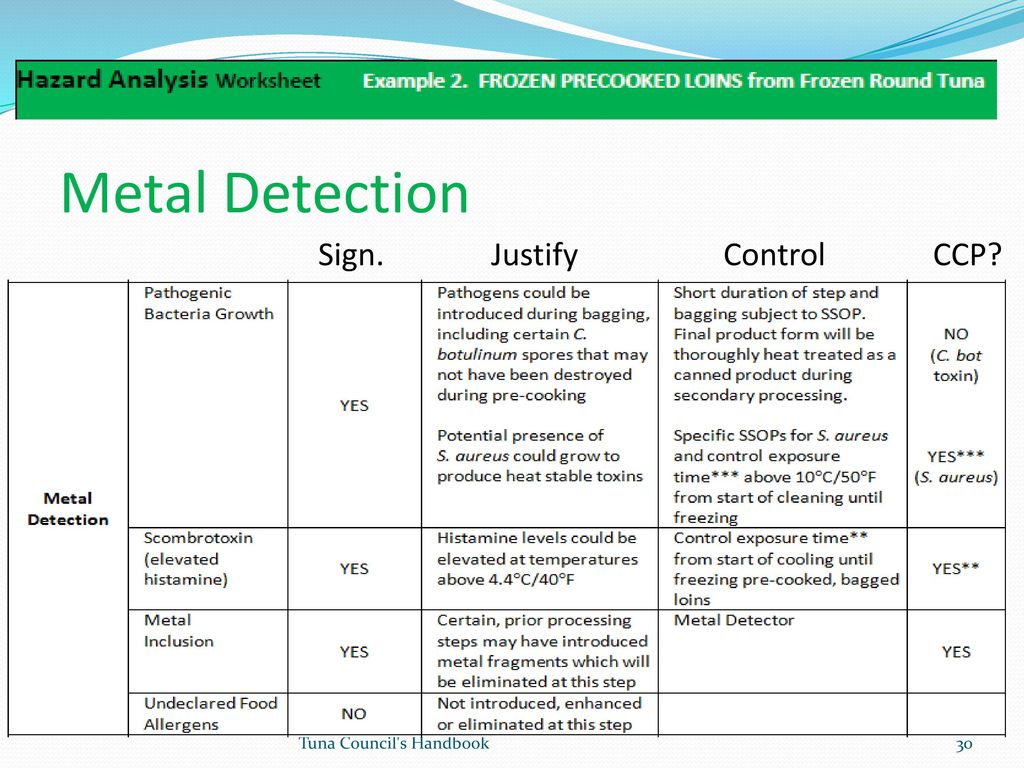

Tuna Haccp Handbook Chapter Haccp Plan Examples Ppt Download

Pdf Review On Hazard Analysis And Critical Control Point Haccp In The Dairy Product Cheese

Ccp Metal Detection Techni K Smart Knowledge For Food Techies

Haccp Introduction 7 Principles Haccp Introduction 7 Principles

Introduction To Haccp Principles Practice Agenda Definitions Review Of Haccp Principles Practical Example Review Of Typical Water Treatment Plant Ppt Download

Section 1 Haccp Hazard Analysis And Critical Control Points Ppt Download

Haccp For Frozen Mackerel Production Download Table

Should Magnets Be Considered As Critical Control Points Magnattack Global Blog

Haccp Introduction 7 Principles Haccp Introduction 7 Principles

Haccp Introduction 7 Principles Haccp Introduction 7 Principles

Haccp Introduction 7 Principles Haccp Introduction 7 Principles

Comments

Post a Comment